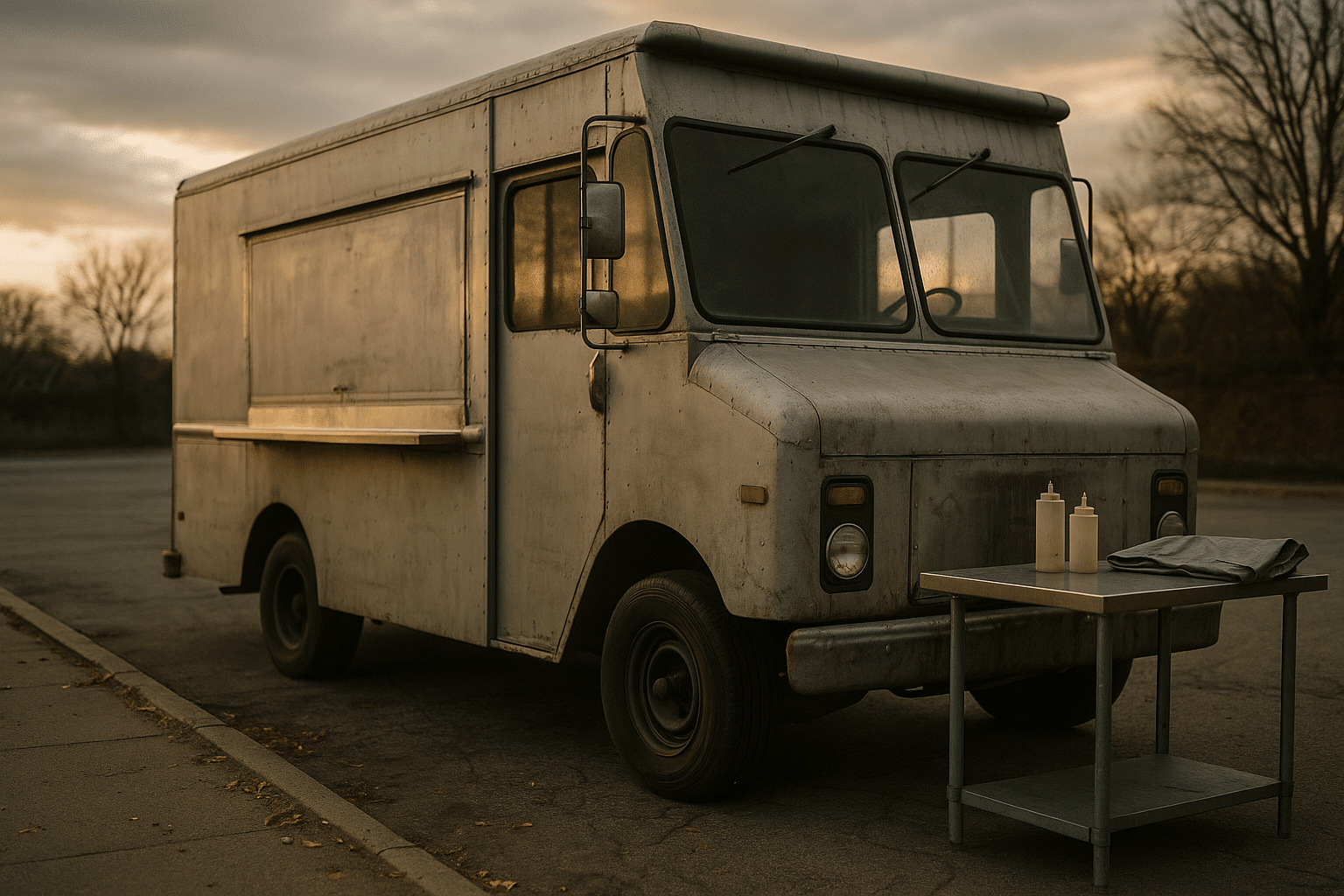

Starting a Food Truck: Costs, Permits, Menu Ideas, and Marketing Tips

Curious what it really takes to roll a kitchen on wheels and serve lines that keep coming back? This guide walks through realistic startup costs, permits and inspections, menu engineering, and marketing that actually moves the needle. You’ll get ranges, simple formulas, and examples you can adapt to your city. If you’re ready to turn a tasty concept into a steady business, let’s map the route.

Outline:

– Section 1: Counting the Real Costs and Building a Startup Budget

– Section 2: Permits, Licenses, and Health Compliance Without Headaches

– Section 3: Menu Engineering, Pricing, and Smart Sourcing

– Section 4: Marketing That Moves: Locations, Social, and Partnerships

– Section 5: Conclusion: Your Roadmap to Roll-Out

Counting the Real Costs and Building a Startup Budget

Before the first sizzle hits the flat-top, sketch a realistic budget. Food trucks can be lean, but they are not cheap. Depending on your city, a reliable used truck or step van with a compliant kitchen build-out often ranges from $45,000 to $120,000. A shell plus a custom build can run $70,000 to $180,000, depending on ventilation, fire suppression, water systems, and equipment. If you already own a suitable vehicle, a retrofit might run $15,000 to $60,000. Beyond the vehicle, plan for permitting, inspections, initial inventory, smallwares, POS hardware, and an operating cushion that carries you through the slow ramp-up months.

To avoid sticker shock, break your budget into categories and set ranges rather than single numbers. Consider these typical line items:

– Vehicle and build-out: $45,000–$180,000

– Safety systems (hood, suppression, fire extinguishers): $2,000–$8,000

– Generator and electrical: $2,000–$7,000

– Refrigeration, hot holding, cooking equipment: $6,000–$25,000

– Permits, licensing, inspections: $800–$7,500 (annualized by jurisdiction)

– Commissary rental (often required): $300–$1,200 per month

– Insurance (liability, auto, equipment): $2,000–$6,000 per year

– Initial inventory and packaging: $1,500–$5,000

– Maintenance and repairs reserve: $1,000–$3,000 set-aside

Map revenue and costs with simple formulas. If your average ticket is $14 and you serve 90 tickets per day, gross revenue is $1,260 for that service. Target prime cost (food + labor) near 55–65%, with food cost usually 25–32% and labor 25–30% for efficient operations. That would leave roughly 35–45% to cover fuel, commissary rent, insurance, maintenance, parking fees, and profit. Use a quick break-even estimate: monthly fixed costs divided by contribution margin per ticket. For example, with $6,000 fixed costs and $9 contribution margin per ticket (ticket price minus average variable cost), you need about 667 tickets per month. An operating cushion of three months of fixed costs helps absorb delays, weather dips, or mechanical surprises. Treat your budget as a living document: revisit after each month’s results, trim waste, and reinvest in high-return improvements such as speed-of-service or a crowd-pleasing menu item that drives add-on sales.

Permits, Licenses, and Health Compliance Without Headaches

Permits can feel labyrinthine, but a clear checklist keeps you moving. Requirements vary by city and county, yet most food trucks will need a business license, a mobile food facility permit, food handler certifications, a fire department sign-off, and proof of a commissary agreement if on-site prep or storage is restricted. Some municipalities require parking location permits, additional street vending permissions, or special event approvals. Expect multiple inspections: health for sanitation and temperature control, fire for fuel and suppression systems, and sometimes building for electrical compliance. Timelines run 4–12 weeks depending on backlog and the completeness of your application.

Core compliance elements include:

– Commissary: Many jurisdictions require daily use of a licensed commissary for water, waste disposal, and food storage. Obtain a signed letter of authorization.

– Food safety: Maintain hot holding above 135°F and cold holding at or below 41°F. Keep calibrated thermometers and logs for cooling, reheating, and daily temperatures.

– Propane and fire safety: Secure propane tanks, ensure leak-free lines, and maintain proper clearances. A maintained suppression system and K-class extinguishers are standard.

– Water and waste: Provide potable water, backflow prevention, and sanitary greywater disposal with labeled tanks.

– Labeling and allergens: Use clear ingredient lists for packaged items and respond to common allergens with training and signage where required.

A strategic approach saves time and money. Call your health department early to clarify which menu items, prep steps, or equipment trigger additional requirements. Submit clean drawings of your truck layout showing sinks, equipment, hood, and tank sizes. Keep a binder onboard with permits, inspection reports, temperature logs, cleaning schedules, SDS for chemicals, and equipment manuals. Train staff to answer inspector questions calmly and accurately. For event-heavy schedules, create a calendar that includes permit deadlines and renewals. Consistency matters: measured cooling procedures, verified sanitizing concentrations, and daily opening and closing checklists protect your guests and your reputation while speeding inspections and renewals.

Menu Engineering, Pricing, and Smart Sourcing

The right menu balances craveability, speed, and profitability. A focused list of 6–10 core items helps throughput and limits inventory complexity. Build around a few versatile base ingredients that cross-utilize well—think one protein deployed three ways, a house sauce that pairs across items, or a single dough used for both savory and sweet. Aim for a target food cost in the 25–30% range; higher-end concepts may run slightly above, but compensate with price, perceived value, and portion control. Track contribution margin for each item, not just percentage food cost, since the dollars each item earns after variable costs fund your fixed expenses.

Use a simple menu matrix to analyze performance:

– Stars: High margin and high popularity—protect quality and consider small price nudges.

– Plowhorses: Popular but lower margin—adjust portions, side options, or bundle pricing.

– Puzzles: High margin but lower popularity—rework naming, placement, or samples to encourage trial.

– Dogs: Low margin and low popularity—consider retiring or seasonal rotation.

Speed-of-service is critical; design items that assemble in under three minutes. Batch and hold thoughtfully with strict temperature control and documented times. Standardize recipes, portion scoops, and garnish cues to maintain consistency during rushes. Packaging influences both perception and cost, so test containers for heat retention, leak resistance, and ease of eating one-handed. Offer a few options for dietary needs, such as a gluten-free base or plant-forward swap, but keep substitutions manageable. Sourcing strategies should hedge volatility: maintain one primary wholesaler and at least one backup, explore seasonal produce from regional distributors, and lock in prices on staples where possible. Track waste daily—trim loss, spoilage, and over-prep are silent profit leaks. Finally, name items with clarity and personality, spotlight a signature offering, and use suggestive selling—upgrade to a combo, add a beverage, or offer a limited-time side that reinforces your brand voice without bloating the line.

Marketing That Moves: Locations, Social, and Partnerships

Marketing a food truck blends geography, timing, and storytelling. Your truck is a rolling billboard, but your real engine is repeatable visibility. Start by mapping foot-traffic zones by daypart—office clusters for weekday lunches, parks or breweries for weekends, and event venues on show nights. Build a weekly route with anchors (high-probability stops) and test slots (new locations). Track performance by stop with simple metrics: tickets per hour, average order value, and weather context. A modest paid boost on social platforms to geo-target people within a few miles of your stop time can nudge discovery without overspending. Meanwhile, direct channels—email and SMS—drive reliable turnout when algorithms drift.

Develop a nimble content plan:

– Post your weekly schedule at the same time each week to build habits.

– Share quick prep clips, sizzling sounds, and behind-the-scenes setup to create anticipation.

– Highlight a rotating special with a clear photo and a concise hook.

– Celebrate user photos and reviews, and reshare with permission.

– Pin a “Where to Find Us” message and update daily locations in your bio links.

Partnerships accelerate reach. Coordinate with local breweries, markets, and community events where food is welcome but kitchens are scarce. Co-create limited-time menu items themed to the venue, share promo assets, and agree on cross-posting. Neighborhood associations, office managers, and residential complexes often book recurring service if you make it easy: provide a one-page pitch with menu, minimums, insurance proof, and a simple booking link. Consider sampling at the start of service to spur the first few orders and create a line that signals demand. Loyalty remains powerful even without complex apps: punch cards, a “10th meal on us,” or a secret menu item for repeat guests encourages retention. As your calendar fills, protect your brand promise—arrive on time, post real-time updates if delayed, and keep a rain plan. That reliability, more than any ad, becomes its own marketing as word spreads through satisfied stomachs.

Conclusion: Your Roadmap to Roll-Out

Turning a compelling food idea into a sustainable mobile business starts with clear math, clean compliance, and a menu that moves fast. From there, consistent operations and thoughtful marketing turn occasional curiosity into steady demand. If you’re planning your launch, map a 90-day runway. Weeks 1–4: validate your concept with pop-ups or a rented cart, refine a focused menu, and build a pre-launch list by inviting sign-ups at tastings. Weeks 5–8: finalize truck layout drawings, apply for permits, secure a commissary, price equipment quotes, and lock in vendors with backup options. Weeks 9–12: soft-launch with three to five service windows per week, gather feedback, adjust recipes and portions, and tighten your route plan. Keep cash flow conservative—prioritize essentials that affect safety, speed, and taste, and delay cosmetic upgrades until revenue stabilizes.

Operate with a dashboard mindset. Track daily:

– Sales per hour and per stop

– Food cost percentage and waste notes

– Labor hours versus tickets

– On-time arrival and service times

– Weather and competing events

Use those numbers to tweak the plan weekly—drop slow stops, double down on high-yield anchors, and run limited-time offers to test pricing elasticity. Remember that momentum compounds: clean inspections, punctual service, and consistent quality make venue partners eager to host you again. Above all, pace your growth carefully. A second truck, a seasonal kiosk, or limited wholesale can come once your first unit consistently hits targets and reserves are healthy. Keep the joy visible—the hiss of the griddle, the shine on fresh herbs, the moment a guest takes that first bite—and pair it with disciplined systems. That balance is your roadmap from hopeful first service to a well-regarded neighborhood fixture on wheels.