Fiberglass Grille: Types, Applications, and Maintenance Tips

Fiberglass grilles quietly do big jobs—shielding openings, managing airflow, and standing up to weather, chemicals, and salt. This guide breaks down what they are made of, the major types you’ll encounter, and where each one excels. You’ll pick up sizing shortcuts, installation tips, and maintenance routines that prevent costly callbacks. Stay for real‑world comparisons that make choosing the right grille feel practical and even a little satisfying.

Outline and Why Fiberglass Grilles Matter

Before diving into specifications and site conditions, it helps to frame what a fiberglass grille actually is. In most contexts, the term refers to a rigid or semi-rigid grid or louvered panel made from fiber-reinforced polymer (FRP) where glass fibers provide strength and a thermoset resin binds everything together. Compared with metals, fiberglass has a much lower density (roughly 1.6–2.0 g/cm³ versus around 7.8 g/cm³ for carbon steel), so panels can be light yet strong, easier to lift into place, and less costly to transport. The material does not rust, tolerates splashes of salt and many chemicals, and is electrically non-conductive—valuable traits for coastal buildings, water treatment sites, and facilities with sensitive equipment. These properties translate into practical gains: fewer corrosion-related shutdowns, simpler maintenance, and consistent airflow or screening over a long service life.

Here is the roadmap for this article, so you know what to expect and where to find it quickly:

– Types of fiberglass grilles: woven meshes, molded and pultruded grids, and louvered panels, with resin options and surface finishes

– Applications: where each type shines—architecture, HVAC, marine, utilities, agriculture, and more

– Specification and installation: sizing for airflow or load, fasteners, thermal movement, cutting, and sealing

– Maintenance and lifecycle: cleaning intervals, inspection, minor repairs, and total cost-of-ownership

– Conclusion: a concise checklist to guide confident selection and long-term care

At a basic level, fiberglass grilles convert the high tensile strength of glass fibers (the fibers themselves can exceed 2,000 MPa; the composite panel’s usable strength will be much lower and depends on fiber orientation and resin) into a lightweight, corrosion-resistant panel. Thermal expansion is moderate and anisotropic in FRP; drilling slightly oversized holes and using slotted connections where spans are large helps accommodate movement. Because fiberglass has low thermal conductivity compared with metals, surfaces feel less “cold” and condensation can be reduced. For airflow uses, a grille’s free area and blade profile determine pressure drop; for protective uses, the aperture and bar thickness govern debris control and impact resistance. That balance—air in, hazards out—is why fiberglass grilles have become a reliable, well-regarded choice across climates and industries.

Types of Fiberglass Grilles: Meshes, Gratings, and Louvers

“Fiberglass grille” can describe several related products, each built around glass fibers embedded in resin but optimized for different roles. Understanding the families will help you match performance to purpose without over- or under-specifying.

– Woven fiberglass mesh: This is the familiar window or insect screen, produced by weaving fiberglass yarns and coating them with resin for stiffness and weathering resistance. Typical thickness ranges from about 0.25–0.5 mm, with apertures sized for insects, debris, or coarse filtration. It offers high open area (often 60–80%), excellent airflow, and modest impact resistance. It’s ideal for keeping out pests while allowing ventilation, and can serve as a primary barrier behind a sturdier exterior guard.

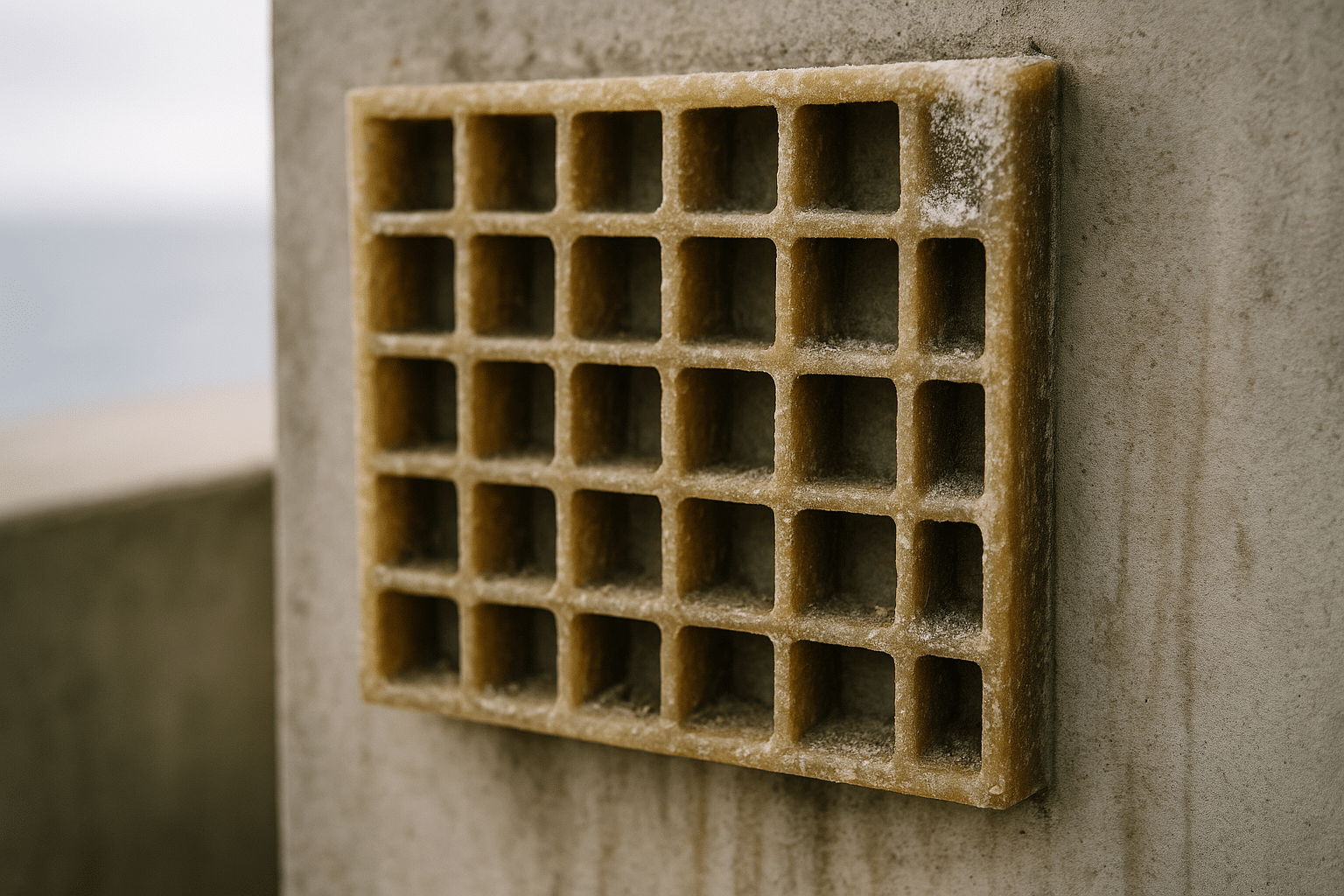

– Molded FRP grating used as grille: In corrosion-heavy environments, molded square-grid panels (commonly 25–38 mm thick) serve as rugged protective grilles over intakes or as guards around equipment. While often used for walkways, their grid structure, high open area (commonly 40–70%), and stiffness translate well to protective screens in industrial settings. They are non-conductive and resist many chemicals, which makes them suitable for wastewater, chemical handling, or coastal installations.

– Pultruded bar grilles and louvers: Pultrusion aligns continuous fibers along profiles, creating straight bars or blades with high directional strength. As louvers, blades are tilted to shed rain and screen direct views while permitting airflow. As bar grilles, the profiles form linear openings with controlled free area and an intentional aesthetic, useful on building facades and mechanical screens.

Resin selection influences durability, temperature tolerance, and fire behavior. For general building exposure, polyester systems are common; where stronger chemical resistance is needed, vinyl ester options are frequently chosen; and in tighter fire and smoke environments, specialized low-smoke systems may be specified. UV inhibitors and color pigments can be integrated to slow fading and chalking. Surface textures range from smooth to gritted; in a grille application, smooth or lightly textured surfaces are easier to clean while still diffusing glare.

Key comparisons to keep in mind:

– Airflow: woven mesh has the highest open area per thickness; louvers trade open area for rain shedding and sight screening

– Impact: molded or pultruded grids withstand higher point loads than fine mesh

– Weight: all FRP options are lightweight, but thin mesh is featherlight; grating is heavier yet still far lighter than comparable metal guards

– Aesthetics: bar grilles and louvers create clean lines; molded grids look utilitarian and emphasize function

Choosing among these types is less about a single superlative and more about fit: whether the priority is airflow, debris control, concealment, corrosion resistance, or a blend of all four.

Applications Across Industries and Environments

Because fiberglass grilles balance airflow, strength, and corrosion resistance, they appear in a surprisingly wide set of use cases. In buildings, they screen rooftop equipment, conceal mechanical rooms, and protect openings from birds and debris. Architects appreciate that pultruded blades can double as sunshades, reducing solar gain while maintaining ventilation. In coastal settings, where wind-driven salt shortens the life of many metals, fiberglass’s stable surface chemistry pays dividends with fewer replacements and less touch-up work. For wastewater treatment and chemical processing, molded grids serve as rugged intake guards that shrug off splashes and fumes that would attack unprotected steel.

HVAC applications benefit from non-conductive, low-maintenance grilles in areas where condensation, cleaning chemicals, or disinfectants are common. Return air and relief openings can use fiberglass louvers that balance free area and pressure drop while avoiding corrosion streaks on surrounding walls. For agricultural buildings, mesh grilles help modulate ventilation without allowing pests or windblown chaff to enter. In marine facilities—ferries, piers, and coastal stations—pultruded or molded grilles resist salt spray and occasional impact from gear, all while keeping air moving through enclosures.

Typical performance considerations by environment include:

– Coastal and marine: prioritize UV-stabilized resin systems, smooth surfaces for salt rinsing, and hardware that matches the corrosion profile (non-corroding or isolated metals)

– Industrial: evaluate chemical compatibility charts for fumes and washdowns; select thicker grids where impact or occasional foot contact is possible

– Public-facing facades: consider bar spacing for sight screening, choose colors that mask dust, and verify the louver angle for rain defense

– Agriculture: optimize aperture to block pests; use easily cleaned meshes to handle dust and organic residue

Temperature exposure often falls between -40 °C and 80–100 °C for many standard resin systems; always confirm the intended range because prolonged high temperatures can soften the matrix and reduce stiffness. Fiberglass is non-magnetic and electrically insulating, which can be advantageous near sensitive equipment or where stray currents are a concern. Finally, because these grilles are comparatively light, installers can handle larger panels, reducing seam lines and simplifying attachment—a practical edge in retrofit scenarios with limited crane access.

Specification, Sizing, and Installation Practices

Good outcomes with fiberglass grilles start with a clear statement of goals: airflow target, debris exclusion, impact resistance, and appearance. For airflow-driven designs, focus on free area and anticipated face velocity. Pressure drop across a grille rises with the square of velocity; if pressure margin is tight, increasing grille area or selecting a profile with higher free area can reduce losses. For debris or pest control, aperture size and wire or bar thickness govern what gets through; a layered approach—fine mesh behind a sturdier grid—can balance protection and airflow.

When specifying, gather these essentials:

– Environment: salt, sun, chemicals, and cleaning methods

– Type: woven mesh, molded grid, pultruded bar grille, or louver

– Dimensions: overall size, module size, and allowable splice locations

– Mechanics: expected wind, snow, or incidental impact loads; required stiffness and deflection limits

– Airflow: target free area, allowable pressure drop, and rain defense if louvered

Resin choice should match conditions. For general exterior exposure, durable polyester systems with UV inhibitors are common; for aggressive chemical atmospheres, vinyl ester improves resistance; in areas with tight smoke development limits, consider low-smoke formulations. Color can be integral, helping conceal dirt or coordinate with adjacent finishes. If brightness and glare matter, matte textures help without turning cleaning into a chore.

Installation is straightforward but benefits from a few habits:

– Allow for thermal movement: use slotted holes or slightly oversized clearances, and avoid rigid, fully restrained corners over large spans

– Select compatible fasteners: non-corroding hardware or isolated metals prevent galvanic interactions; use washers to spread loads on thin meshes

– Field cutting: carbide or diamond blades produce clean edges; support the panel to avoid chipping, and cut slowly to manage heat

– Edge sealing: seal cut edges with compatible resin to maintain moisture resistance and appearance

– Alignment: for louvers, verify blade pitch and orientation, and confirm that drip edges face outward for rain management

Quality checks help avert callbacks. Inspect for uniform color, consistent fiber wet-out, and absence of voids at intersections on molded grids. Confirm that free area matches design assumptions and that anchors engage solid structure, not just sheathing. Where panels sit near walking surfaces, verify that openings comply with safety guidelines for finger and object entrapment. A small commissioning pass—ensuring doors clear, dampers operate freely behind the grille, and drains aren’t blocked—pays off quickly.

Maintenance, Lifecycle Value, and Conclusion

One reason fiberglass grilles are highly rated in demanding environments is their low, predictable maintenance. Routine care focuses on cleaning, quick inspections, and simple touch-ups after field cuts. Because the material doesn’t rust and resists many chemicals, upkeep typically involves periodic rinsing and mild detergents, not abrasive blasting or heavy recoating.

Adopt a practical maintenance rhythm:

– Quarterly rinse in dusty or coastal areas; semiannual elsewhere

– Mild detergent wash with soft bristle brushes to lift grime; avoid harsh solvents unless confirmed compatible with the resin

– Inspect connections for loosened hardware, especially after storms or thermal extremes

– Check for UV chalking on sun-exposed faces; if appearance matters, consider a light protective coating compatible with FRP

– Seal any new field cuts with resin to keep edges closed against moisture and discoloration

Minor repairs are manageable. Hairline surface cracks or chipped corners on molded grids can be filled with resin patch kits; deeper damage warrants panel replacement, which is simplified by the light weight and modular nature of many products. In airflow applications, verify that pressure drop remains within design ranges after cleaning; a simple manometer check across the grille can flag clogging from lint or coastal salts.

Lifecycle cost is where fiberglass often stands out. Lower installation labor (thanks to lighter panels), infrequent replacement in corrosive settings, and minimal coatings can offset higher initial material cost compared with commodity metals. Environmentally, extending service life reduces disposal volume and replacement manufacturing impacts. While FRP recycling options are still developing in many regions, re-use as secondary guards or barriers is often possible when a grille is decommissioned.

Conclusion and next steps: Define your performance priorities, shortlist the appropriate fiberglass type, and verify resin compatibility with the environment. Size for airflow or load with comfortable margins, allow for thermal movement at supports, and plan simple, regular cleaning. This combination yields durable, low-fuss screening that protects equipment, supports clear air paths, and keeps facades tidy. With a measured approach, fiberglass grilles become a quiet but dependable part of your project’s long-term resilience.